The Climber’s Grip

Learn about a rock climbing training tool (called “GettaGripz”) made by Gabe at Maker Works. Read to the end to see how it works!

Getting Started: What to Make?

When Gabe, a computer science student and rock climber, needed tools for a class project, he found Maker Works. His goal: a portable hangboard to train grip strength anywhere. (His secondary goal: a good grade in the class!)

-

A hangboard (or fingerboard) is a tool used by rock climbers to train finger strength by hanging your body weight by your fingers.

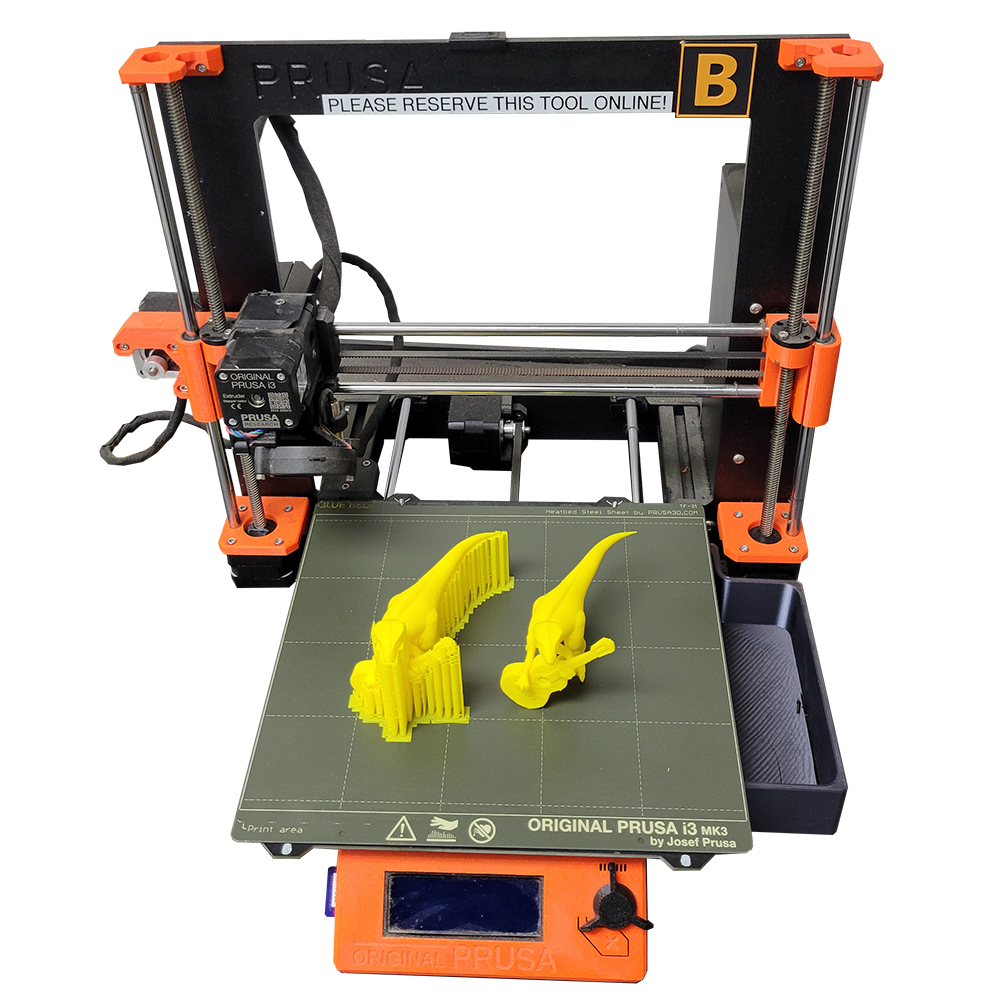

Gabe had browsed our website and noticed that we not only have a wood shop but also 3D printers and laser cutters. That sealed the deal for him and he scheduled a tour. A week later, he took the Drill Press/Bandsaws Checkout Class, the Prusa 3D Printer Checkout Class, and purchased our discounted student membership for $60/month.

At the start, Gabe believed that 3D printers and bandsaws were all he needed. For the first 2-3 months, he would come in and 3D print the inserts for his product while bandsawing the major shape (first three prototypes below).

The evolution of Gabe’s prototypes, over the span of a year!

The Project: Challenges, Solutions, and Success

The parts worked, but they were inconsistent and rough. So, a few months later, he realized the CNC router would be his real ticket to mass production, where he could cut shapes that were cleaner and more precise. He also learned that not all woods behave the same, and, after some trial and error, settled on Baltic birch plywood (instead of assorted woods from his dad’s basement).

-

In Gabe’s words: “It works great with the ShopBot because it doesn’t splinter, and I also like the look of the exterior layers on the blocks.”

-

CNC stands for Computer Numerical Control and is used to describe any machine that is controlled through computer instructions.

The ShopBot is our 4’x8’ CNC router that can work on woods, plastics, cardboard, and some hard foams. It lets you repeat operations but also accomplish detailed movements like fine engravings and subtle curves.

Gabe cutting out each layer on the ShopBot CNC router

Gabe had used a CNC router before, but never on his own. At Maker Works, he could finally run it all by himself, so he took the ShopBot CNC Router Checkout Class and left the bandsaws and 3D printers behind.

Six grips stacked on each other, fully finished

Instead of cutting one block at a time, he opted to build each GettaGripz like a sandwich. Thinner sheets of wood were cheaper and easier to work with, so he cut out layers on the ShopBot and glued them together.

Each prototype went to his climbing friends for testing. They’d tell him when the magnets were too weak, when the grip felt uncomfortable, or when the mechanism was confusing. With every round of feedback, Gabe rebuilt with more energy, knowing each version was bringing him closer to success.

The laser cutter was the final step of the process, engraving his logo onto each block.

Gabe on the router table, beveling the edges of the grip

Gabe’s collection of completed grips (laser engraved as well)

Looking Ahead: What’s Next?

Gabe believes the GettaGripz is finally complete. Click through the images on the right to see its features.

Next, Gabe is gearing up to advertise GettaGripz to the rock climbing world. He’s working on learning new skills like video editing and marketing, in hopes that this product will reach the right audience.

INCLUDED IN THE KIT:

Custom laser engraved cotton bag

Medium-strength resistance band

3 inserts (7mm, 10mm, 15mm)

Base distance is 25mm

And, of course, the official GettaGripz block

Keep up to date with Gabe and the GettaGripz on his website!

Tools (Initial designs)

Prusa 3D printer

Little wood bandsaw

Router table

Tools (Final Product)

ShopBot CNC router

Laser cutter

Materials

Baltic birch plywood delivered to Maker Works from All America Plywood (Detroit supplier)

Small circular magnets and resistance bands from Amazon