The GroundLock

Learn about how a team of high school students won an innovation award with this topsoil-saving design

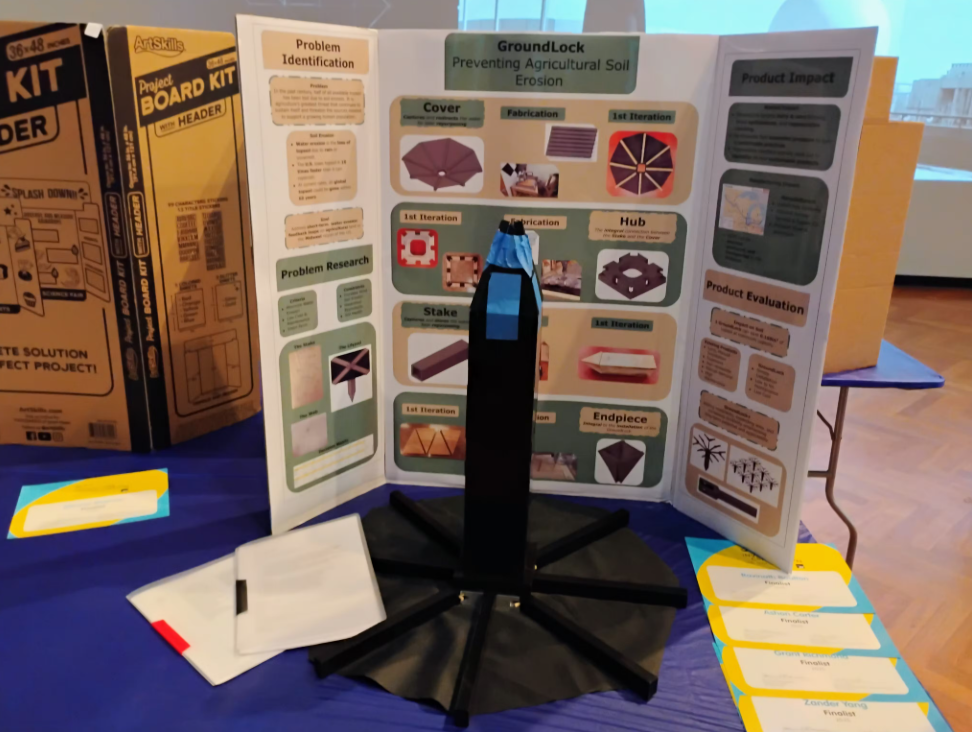

The winning photo!

Getting Started: What to Make?

Soil erosion is a serious problem in agriculture. Without healthy topsoil, crops can’t grow, and farmers risk another dust bowl. A team of Huron High School students — Ashon, Ravi, Zander, and Grant — decided to tackle this problem through the Invention Convention, a K-12 competition where students design solutions to real-world problems. They call their idea the GroundLock.

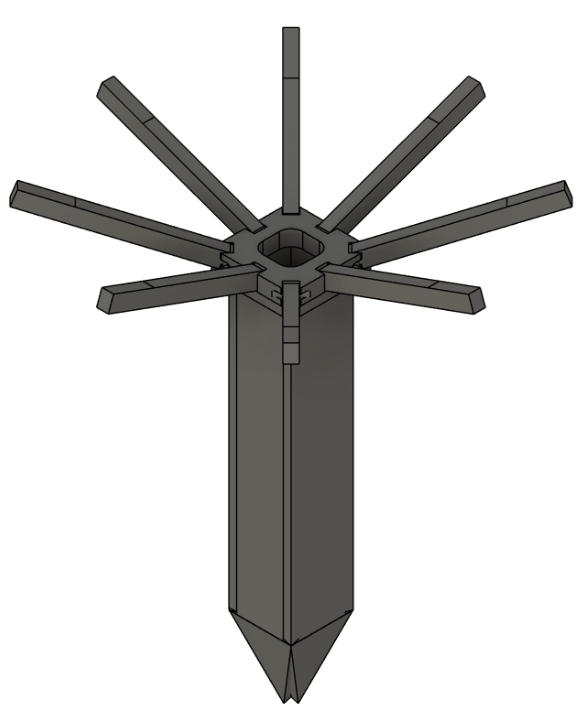

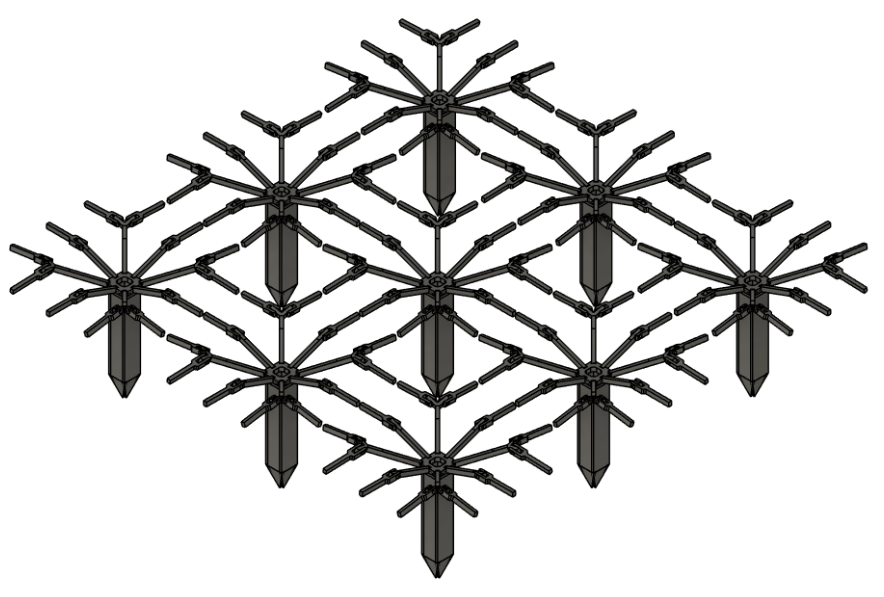

The final design of the GroundLock in Fusion 360, waiting to be turned into a reality

The GroundLock has four main parts:

The Cover — a waterproof fabric stretched over eight arms that will collect water like a reverse umbrella

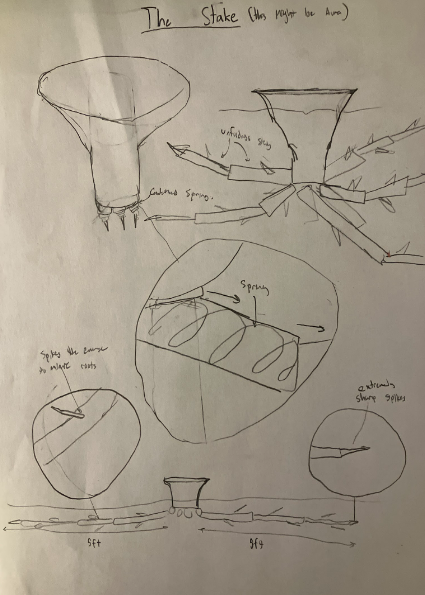

The Stake — a funnel that will store the water for later use

The Endpiece — the pointy end that goes into the ground

The Hub — the connecting piece between the Cover and Stake

The Project: Challenges, Solutions, and Success

The Hub is what brought the team to Maker Works. The students quickly realized that its complex design would need to be sturdy and precise, so they wanted it out of aluminum. The best machine for that would be a CNC mill, which their school shop did not have.

Luckily, Grant was already familiar with Maker Works through his high school FIRST Robotics team, and he’d taken the Mills Checkout Class a year before so he knew what the machines were capable of. He got the rest of the team to take the class, and then they were faced with the real challenge: using the CNC mill.

-

FIRST (“For Inspiration and Recognition of Science and Technology”) is a nonprofit organization that organizes robotics competitions around the world. Most people encounter it through robotics clubs in high schools.

Maker Works supports several FIRST Robotics teams through discounted memberships, classes, and exclusive space for meetings in the Conference Room.

-

The Tormach is a computer controlled (or, “CNC”) milling machine that takes a digital design and carves it into metals or plastics with precision.

How precise? Its positioning accuracy is one-thousandth of an inch. A skilled human hand can work to about a hundredth of an inch (at best).

Early drawings of the Stake design

In order to use the Tormach, you need two things:

The ability to operate the machine! The Mills Checkout Class at Maker Works gives students access to both the Bridgeport manual mill and Tormach CNC mill, as well as a solid foundation in milling principles in just 4 hours.

A design/instructions the machine can follow! For a manual mill, you would do everything by hand, turning handwheels and lowering quills. But for a CNC mill, the majority of the work happens on a computer.

The team had #1 checked, and now it was time for #2. They already knew CAD (Computer-Aided Design) through the high school’s PLTW program, but they needed CAM (Computer-Aided Manufacturing) to turn their drawings into machine instructions. With the help of our Fusion 360 CAM Skill Development class, they learned the full CAD-CAM-CNC toolchain.

-

CAD (Computer-Aided Design) is the process of creating a digital design, CAM (Computer-Aided Manufacturing) is the process of converting a digital design into instructions for a computer controlled machine, and CNC (Computer Numerical Control) refers to tools that are controlled by computers, like the Tormach.

Other CNC tools at Maker Works include: laser cutters, embroidery machine, vinyl cutter, 3D printers (yes really!), ShopBot wood router, plasma cutter, and PCB engraver.

Learning how to use any one of these tools will make it easier to learn the others.

The Hub being machined on the Tormach CNC mill

-

G-code is a programming language for controlling CNC tools. A G-code file is a list of instructions for a tool to follow, like “move to this location at this speed” and “spin at this RPM”. G-code can be written manually, but most of the time it is generated using software like Fusion 360.

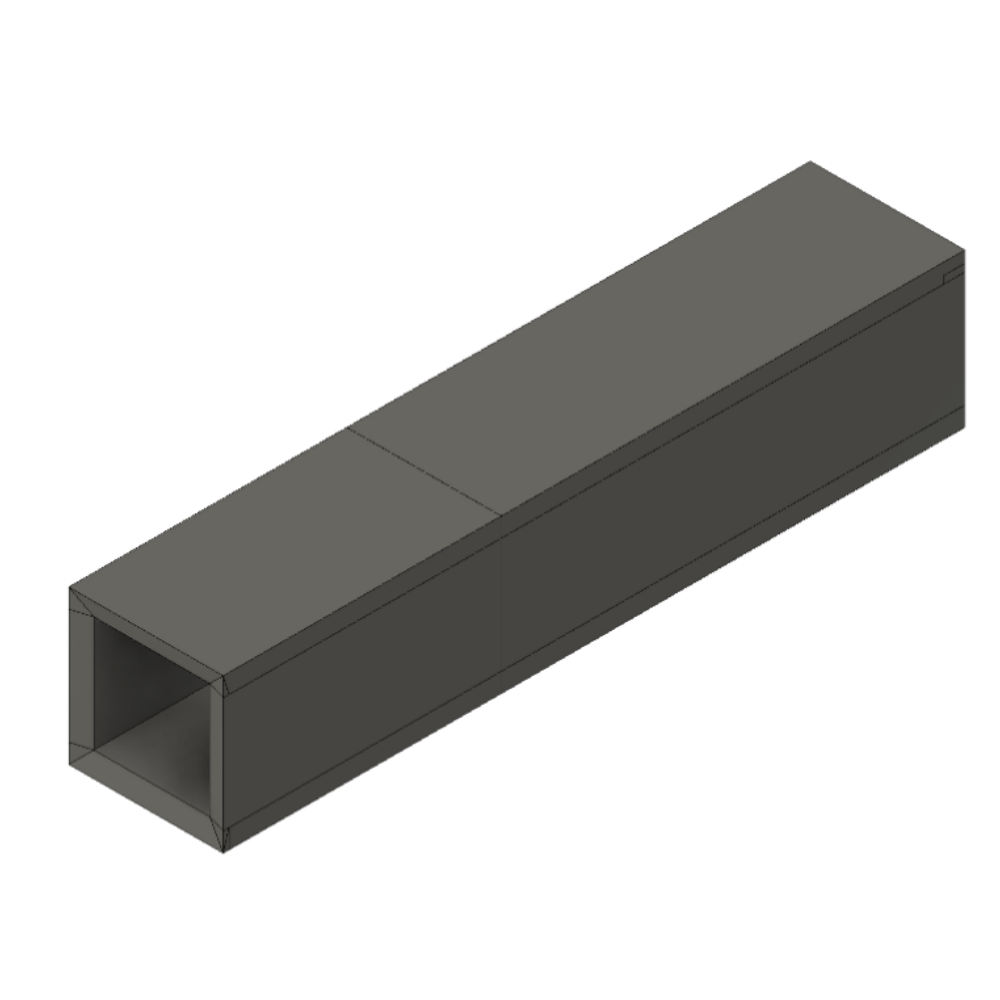

Their first Hub came off the mill, but it wasn’t quite right. The arms needed to rest at an angle, and they wanted the Hub to connect to the Stake without screws or glue. So, the team 3D-printed a “Sub-Hub” to adjust the arm angle while keeping the aluminum Hub intact.

After winning at the State Invention Convention, the team kept refining. They replaced the plywood Stake with high-quality HDPE plastic, resulting in a much nicer prototype that more closely resembled what their final product will be.

Looking Ahead: What’s Next?

The GroundLock is still evolving. The team is now working on ways to reuse the collected water automatically, not just store it. They also want to improve how the Hub and Stake fit together, increase durability, and add modularity. Thanks to their success at Nationals, they’ll have free legal support if they pursue a patent.

How a modular GroundLock might look

Tools

Tormach CNC mill

Materials (first & second prototypes)

Plywood from McMaster-Carr

Aluminum plates from Amazon

Umbrella fabric from Fabric Wholesale Direct

HDPE plastic from McMaster-Carr

Dowel rods from Amazon