A Modern, larger, more powerful CO₂ Laser for the community

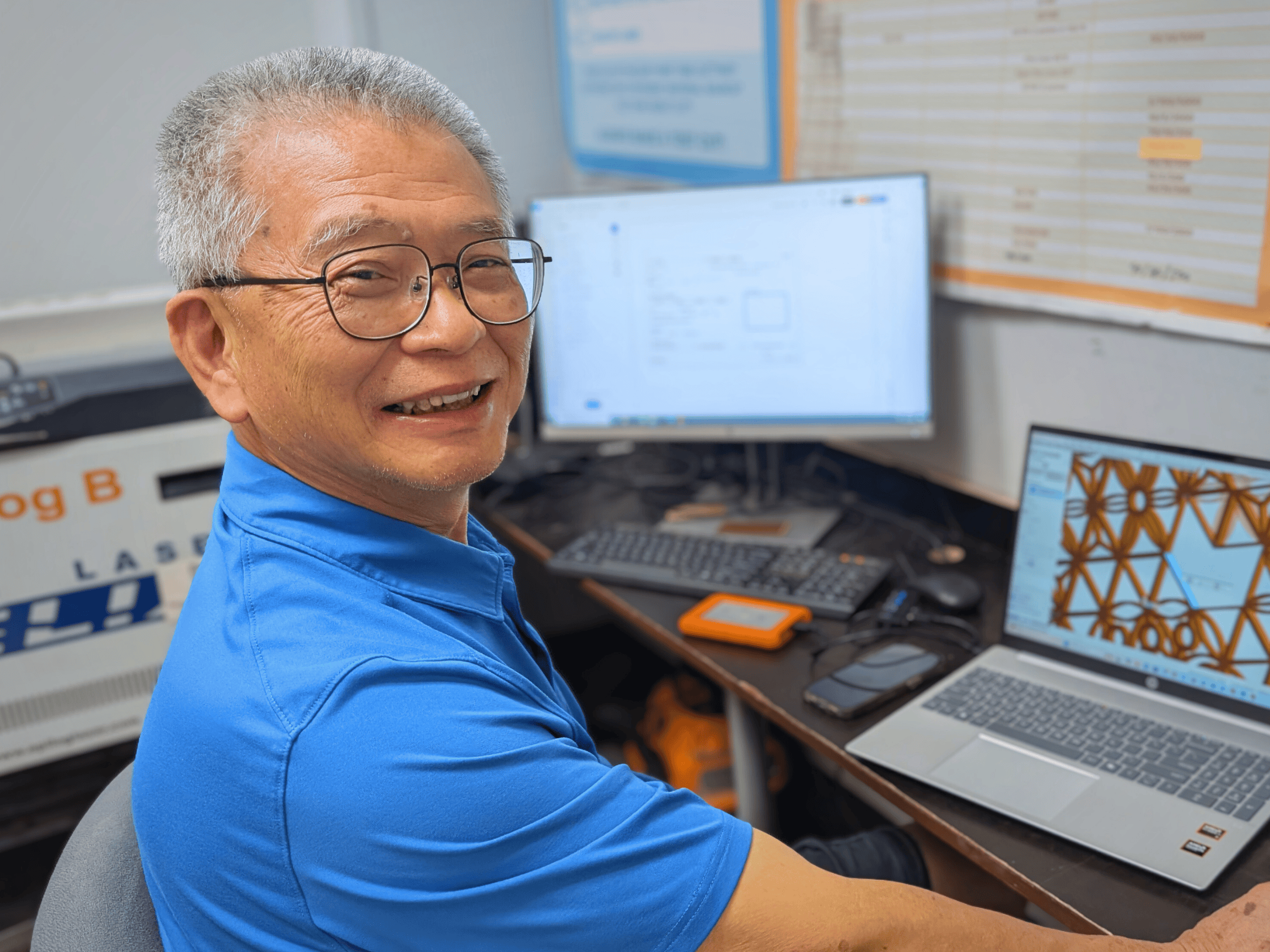

Chris creates a beautiful art for his family and friends using the lasers at Maker Works.

There is no shortage of high quality options out there. There’s no better time to upgrade than now!

The community has been pushing the limits of our Epilog Mini Helix for over a decade! We have about $1,000 set aside from last year’s fundraiser to bring it back to full power, but even then we know people struggle to get through 1/4” material, the 24” x 12” bed size is often too small for many projects, and the outdated user interface makes it harder for new users to learn modern digital fabrication workflows. It’s time for an upgrade.

Who will use this?

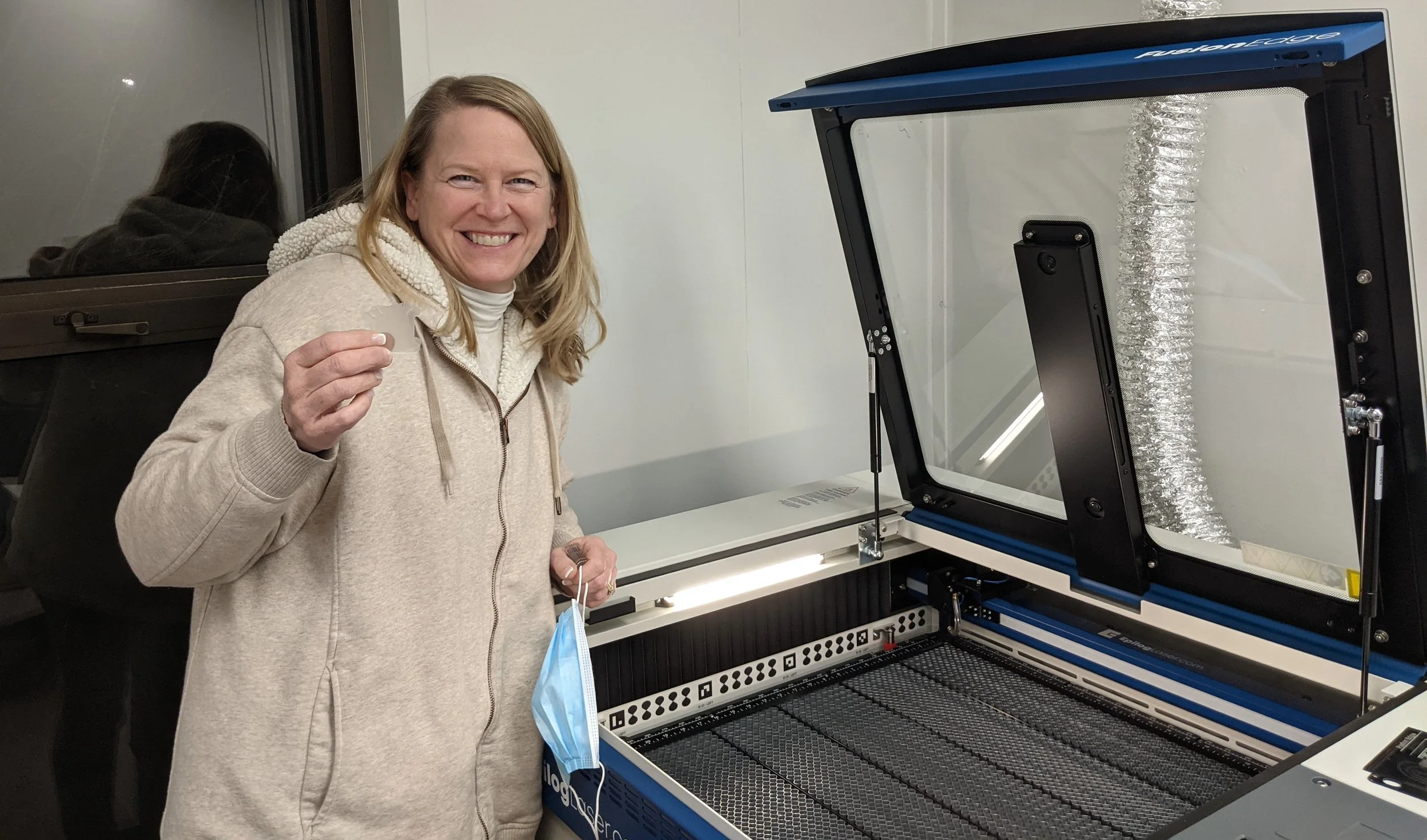

Gail Winger launched GW Stichin Depot after having success on our lasers, she even purchased her own!

The lasers at our shop have introduced thousands of people to CNC and digital design. Countless students have discovered computer aided design (CAD) for the first time. It’s one of the most versatile “gateway tools” we have for engaging youth, artists, engineers, and small business owners.

It has helped launch or accelerate numerous local businesses ranging from young entrepreneurs like Izzy Sutton and Zach Malott to established makers like Creative Corners, Elderwood Academy, GW Stitchin Depot, Saving Throw Pillows, Elophina, and Made by Brad and so many more. The machines see regular use by local researchers and bootstrapped startups, many of whom would not be able to do their work without the tools and community at Maker Works!

Thanks to the Rotary Club of Ann Arbor, we’re looking forward to giving teens free access to this tool in 2026!

Pam launched her puzzle making business ‘Creative Corners’ with her access to the lasers at Maker Works

Cost of a Community-Ready Upgrade

$8,500, approximately. A reliable, easy-to-use, high-duty-cycle CO₂ laser suitable for continuous public use is a significant investment. Quality matters: we need reliability, a modern workflow, and a machine that will last 8–10+ years with proper care. We know how to maintain these machines to make sure the community gets the most value from it, and we firmly believe shared access to a high quality tool is better economically and environmentally.

technically, what will a new laser support?

Made by Brad provides custom lasered glassware, born out of Maker Works!

Larger bed (24" × 18" or greater) → Bigger projects, signage, furniture parts, and expanded curriculum.

Higher power (~80 watts) → Faster cutting, more materials, less waste, and improved throughput for all.

Modern interface & software → Dramatically easier learning curve, enabling thousands more people to confidently use the tool.

This means greater access to hands-on training, more entrepreneurial success stories, and expanded STEM learning for youth.

You can help!

Whether you can provide a financial contribution, or are a manufacturer or distributor of lasers (email us!), we would love your support.

A new, high-quality CO₂ laser will fuel the next decade of creativity at Maker Works by empowering thousands of students, artists, engineers, youth programs, FIRST Robotics teams, and small businesses across Washtenaw County. It will be one of the most visible and impactful upgrades we can make for our community. Maker Works has a strong history of supporting tool access in a welcoming, shared environment that helps the community grow. We would love for you to help be a part!

Students in our Laser Class learned how to design and create custom reusable name tags, just one small project out of thousands!