Join us for our 13th Anniversary Open House on Sunday, October 13th! Please help spread the word via this link.

We're opening up another Metal Shop Fab Track and a brand new Textiles Track, and registration closes this week for the Intro to Wood Carving course!

Join us at Tech Trek on Sep. 27th with The Future Innovators Academy, and Sep. 29th at the Zero Waste Fall Festival at Kiwanis!

Finally, our next Shop Improvement + Game Night is Saturday, Oct. 5th!

Read on for details, and thank you for being a part of our community!

Join us for an epic afternoon of tool demonstrations, fantastic member projects, and tours through the entire shop!

THREE BIG ASKS!

1. Register for the event! Say hello, collect a coin, maybe a Maker Works' giveaway (you'll have to attend to find out!), and learn about new upcoming programming!

2. Volunteer! We're looking for a few people that can demo some tools or help offer tours (You'll have a guide) : ).

3. Share this event with that person you know that's been meaning to see the shop, or a company interested in sponsoring : ).

Class Tracks in Wood, Metal, and Textiles!

Wood Carving Track

Sundays 9/29 - 11/03

Registration Ends 9/19! Dive into the transformative art of wood carving with expert sculptor Mike Kapetan across six sessions in our quiet morning woodshop!

Metal Shop Fab Track

Sundays 10/13 - 11/03

Open the doors and get comfortable with basic metal fabrication via welding, plasma cutting, drilling, punching, grinding and more in this four part series.

Textiles Track

Saturdays 10/19 - 11/09

Learn to use the most popular textiles tools: The Bernina Active, Consew Industrial Sewing Machine, and CNC Amaya Embroidery to customize a classic canvas zipper bag!

Member Project Spotlight

Project ready for delivery!

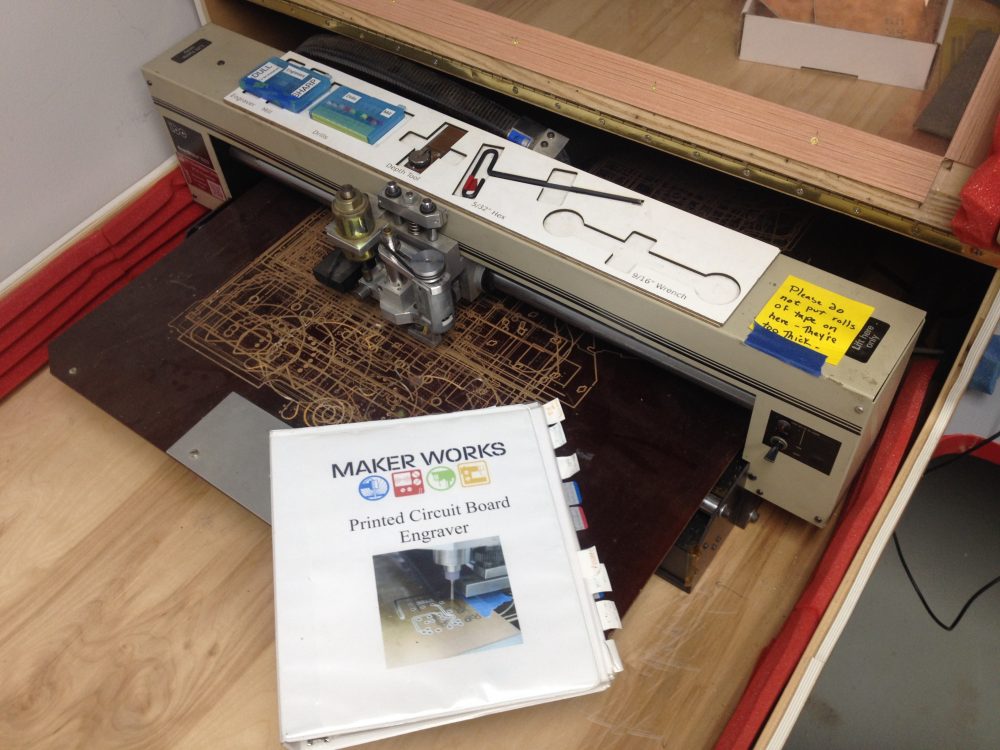

A few weeks ago the shiny basketball on the right was a solid cube of aluminum. High school student Elliot learned a number of processes from Fusion 360 CAD and CAM to 3D Printing and operating the Tormach CNC Mill. And just a little bit of buffing : ) Nicely done Elliot!

The resources at Maker Works are invaluable, people are capable of doing amazing things when they have access. Thanks to all of you who have helped support Maker Works, and thus students like Elliot!

What's Elliot's next project?

A couple different setup operations on the Tormach CNC Mill

Do you like shiny?

Upcoming Activities

Tech Trek

Friday, Sep. 27

The Future Innovators Academy has invited us to join their booth at A2 Tech Trek. Come check out the hundreds of participating tech organizations from Ann Arbor all in one place!

Zero Waste Festival

Sunday Sep. 29th

Join us at the Zero Waste Festival at Kiwanis! We'll be there running repair demos, converting old shirts to shopping bags, running upholstery demos, and promoting tool use!

Got Kids?

Starts This Week!

The Future Innovators Academy fall workshops start THIS week! Robotics, LEGO Robotics, Coding, Digital Art, Game Design and a whole lot more.

Whether you're interested in helping keep the shop clean, help repair community items, introduce household tools to young adults, want to help demo a tool, run a tour, mend some clothes, we've got a number of friendly options. Learn more, and sign up here!

FREE: Tours, Classes, and Repairs!

Thank you Kiwanis!

Free Tours

Last year Maker Works ran over 150 free tours of the shop. Over the next 12 months we're hoping to double that with support from Kiwanis!

Take a tour as an individual, or request one for your group!

Free household tools class

Maker Works offers an 'Intro to Intro to Household Tools' workshop that typically costs $80 / person. With support from Kiwanis we're able to provide free access for individuals, and make them available on request for groups!

Free Repairs

We estimate over 100 household items were repaired last year. Saving money, reducing waste, and emphasizing repair! Thanks to Kiwanis, we're able to continue running this activity every third Friday of the month!

These opportunities happen thanks to Kiwanis and the volunteers that help! Find out how you can volunteer here, or sign up to be notified about volunteering here!

Cleaning, Pizza, and Game Night

Saturday, September 7th!

A huge THANK YOU to the dozen people that came out in September to improve the Metal Shop, let’s do it again!

Shop Cleanup!

It's time for a clean-up in the loading dock! Join us 4pm - 6pm on Saturday, October 5th to get dirty and clean-up the Wood Shop.

Pizza!

We were told that offering pizza increases the likelihood you will sign up to help clean shop!

Rumor has it there may be BBQ as well : )

Game Night!

4pm - 11pm, all ages, all are welcome!

Bring and share a game and snacks, or take advantage of Randy's impressive library. Free and open to all ages!

September Classes and Beyond!

Classes are posted on the website through September! Ready to learn? No membership required!

Choose your class and sign up today.

Don't see a date that works for you? Use the 'Request a Class' button to let us know your availability and we'll match you up with an instructor!

What's YOUR favorite online resource?

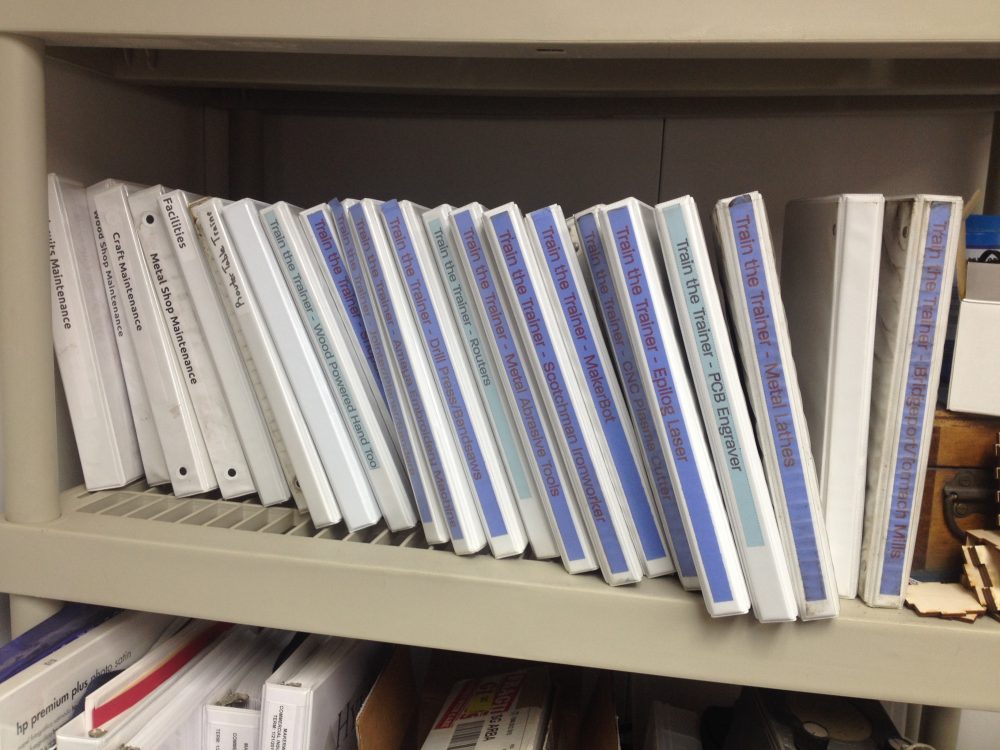

Thanks to your feedback, we had some nice additions and updates to our semi-hidden Materials & Resources page!

Next up, tell us your favorite online resource for information! Web sites, articles, youtube channels, tiktok videos, etc. Let us know!

Thank YOU Kiwanis Club of Ann Arbor!

Thanks to a grant from the Kiwanis Club of Ann Arbor, Maker Works is able to:

Expanded Community Partnership Support (coming soon!)

Kiwanis has been a huge resource to the Ann Arbor community and beyond for over 100 years. We are thrilled to have their support!

As always, you can also support shared access to resources by:

Taking a class or starting a membership!

Sharing this newsletter with someone you know

New sponsorship opportunities to support the shop are coming soon, let me know if you'd like to be first to know!

Thank you!

Josh Williams